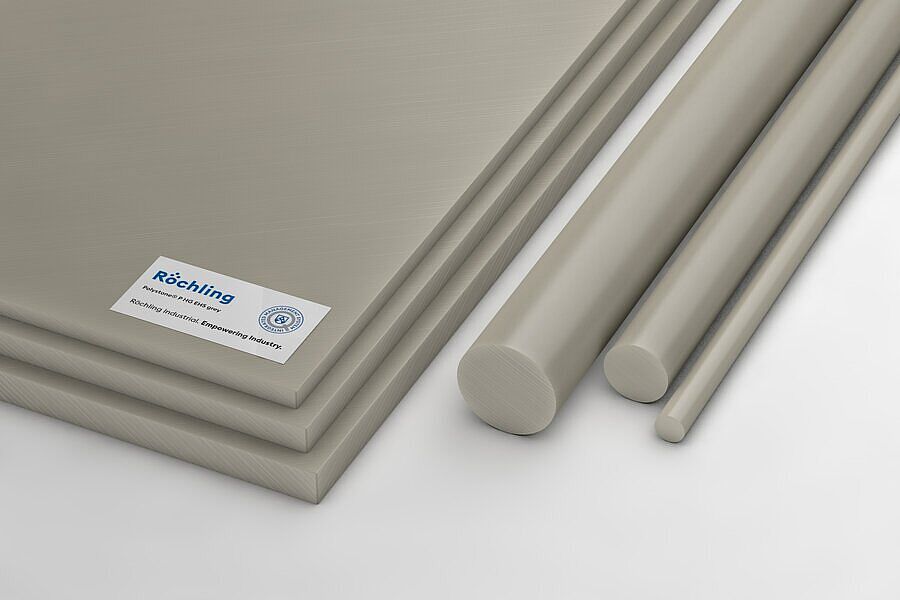

Polystone® P HG EHS grey

PP

High-performance polypropylene especially for the Healthcare industry

In addition to its good hot steam sterilizability, this special material has good machinability and excellent chemical resistance. Polystone® P HG EHS is an isotactic, highly heat-stabilized polypropylene that is available as a homopolymer. This unique property profile makes it perfect for components for respiratory equipment or for applications in the pharmaceutical industry, either as a distribution unit, components for drug production or in chromatography.

Characteristics

- Good sterilisation resistance

- High rigidity

- ISO 10993-5 tested on semi-finished product

- Corrosion resistant

- Chemical resistant

Industries

We are a system supplier and partner from the idea to the OEM's end product - as a cooperative value contribution. We are able to support the healthcare industry at the highest level.

Industry Manager Healthcare - Mail: AReuner@roechling.com

Variants

| SKU | Name | Type | Type | Color | Measurements | Length | Width | Thickness | Height | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| No stock item (MOQ) | 854437 | Polystone® P HG EHS grey extruded | rod | rod | quartz grey, similar RAL 7039 | Ø 45 x 3000 mm | 3,000 mm | 45 mm | |||

| No stock item (MOQ) | 854440 | Polystone® P HG EHS grey extruded | rod | rod | quartz grey, similar RAL 7039 | Ø 30 x 3000 mm | 3,000 mm | 30 mm | |||

| No stock item (MOQ) | 854445 | Polystone® P HG EHS grey extruded | rod | rod | quartz grey, similar RAL 7039 | Ø 55 x 3000 mm | 3,000 mm | 55 mm | |||

| No stock item (MOQ) | 854446 | Polystone® P HG EHS grey extruded | rod | rod | quartz grey, similar RAL 7039 | Ø 65 x 3000 mm | 3,000 mm | 65 mm | |||

| No stock item (MOQ) | 854453 | Polystone® P HG EHS grey extruded | rod | rod | quartz grey, similar RAL 7039 | Ø 45 x 1000 mm | 1,000 mm | 45 mm | |||

| No stock item (MOQ) | 854456 | Polystone® P HG EHS grey extruded | rod | rod | quartz grey, similar RAL 7039 | Ø 30 x 1000 mm | 1,000 mm | 30 mm | |||

| No stock item (MOQ) | 854461 | Polystone® P HG EHS grey extruded | rod | rod | quartz grey, similar RAL 7039 | Ø 55 x 1000 mm | 1,000 mm | 55 mm | |||

| No stock item (MOQ) | 854462 | Polystone® P HG EHS grey extruded | rod | rod | quartz grey, similar RAL 7039 | Ø 65 x 1000 mm | 1,000 mm | 65 mm |

Technical Specifications Polystone® P HG EHS grey extruded

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | 0,92 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | 35 |

| Elongation at break | DIN EN ISO 527 | % | 35 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 2100 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | 4,5 |

| Ball indentation hardness | DIN EN ISO 2039-1 | MPa | 110 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 168 |

Technical Specifications Polystone® P HG EHS grey pressed

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Density | DIN EN ISO 1183-1 | g / cm3 | >0,90 |

| Water absorption | DIN EN ISO 62 | % | 0,1 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Yield stress | DIN EN ISO 527 | MPa | >30 |

| Elongation at break | DIN EN ISO 527 | % | >50 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | >1500 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | >4 |

| Shore hardness | DIN EN ISO 868 | scale D | >70 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Melting temperature | ISO 11357-3 | °C | 162 ... 167 |

| Thermal conductivity | DIN 52612-1 | W / (m * K) | 0,20 |

| Thermal capacity | DIN 52612 | kJ / (kg * K) | 1,70 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 120 ... 190 |

| Service temperature, long term | Average | °C | 0 ... 100 |

| Service temperature, short term (max.) | Average | °C | 150 |

| Vicat softening temperature | DIN EN ISO 306, Vicat B | °C | 95 |

| Test Method | Unit | Guideline Value | |

|---|---|---|---|

| Volume resistivity | DIN EN 62631-3-1 | Ω * cm | >1014 |

| Surface resistivity | DIN EN 62631-3-2 | Ω | >1014 |

| Dielectric strength | IEC 60243 | kV / mm | >40 |