Food safety and efficiency – Optimised production with SmartMarker®

In industrial food production, high output and premium quality are key. Plant operators must maximise production efficiency while reducing downtime, and engineers are tasked with designing robust, high-performance systems that meet stringent hygiene and safety standards.

Fields of application

Our plastics – available as semi-finished products, machined parts, or fully assembled components – have proven themselves in a wide range of food industry applications. Whether in meat, fish and poultry processing, bakery and confectionery production, or the beverage sector – our materials deliver maximum reliability and meet the industry's highest hygiene and safety requirements.

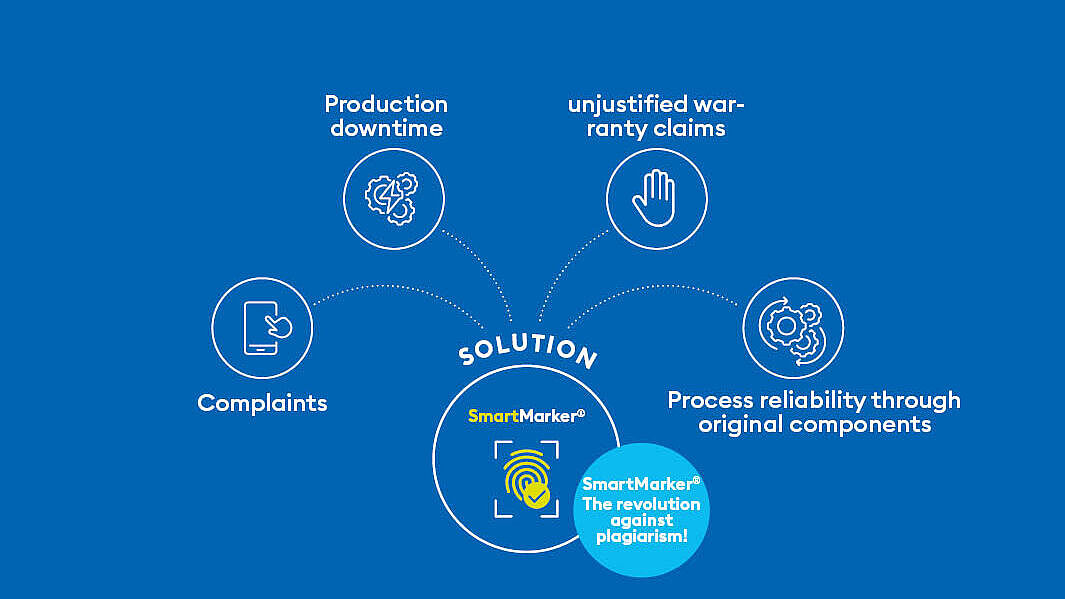

Process reliability through original components

Have you ever faced a situation where a customer claimed that a defective part came from your production—leading to downtime, damages, and reputational risk?

This is where SmartMarker® makes the difference: The technology allows you to verify whether a returned component is genuinely yours, reject unjustified warranty claims, and avoid costly disruptions.

SmartMarker® ensures that only your original parts are used in production – increasing process reliability across the board.

Your commitment to safety in food production

Our plastics marked with SmartMarker® offer maximum reliability for demanding food industry applications. They are approved for direct contact with food and comply with both EU Regulation 10/2011 and FDA requirements.

Our materials

- Sustarin® C ID

- Polystone® D ID

- Sustadur® PET ID

- Sustamid® 6 ID

- SustaPEEK ID

*Other materials are also available as

SmartMarker® variants upon request.

Your advantages at a glance

Your standard plastic just became smart! The material retains its proven properties – the only difference is the addition of microscopic marker particles embedded in the polymer. The “ID” suffix indicates that your product contains these particles and can be clearly identified as your original component.

Röchling's Sustarin® C ID and Polystone® D ID have been approved for direct food contact by the FDA. The “ID” designation not only stands for smart identification, but also confirms compliance with EU Regulation 10/2011 and the U.S. Food and Drug Administration (FDA) requirements.

In addition to Sustarin® C ID and Polystone® D ID, our materials Sustadur® PET ID, Sustamid® 6 ID and SustaPEEK ID also meet these high standards. Röchling thus offers a broad range of technically advanced plastics for direct food contact applications. Other Röchling materials can also be supplied with SmartMarker® technology upon request.

Your product becomes truly unique – like a fingerprint. This ensures it can be identified anywhere and at any time. All you need is a specially developed handheld scanner for SmartMarker®. It detects whether marker particles are present in the material – giving you proof of authenticity.

Using the SmartMarker® scanner, the embedded particles are detected directly in the component. If markers are found, the part is verified as an original.

Is it your product? Yes or no – no doubt.

Each SmartMarker® part can be assigned a digital product passport containing all relevant information – enabling secure traceability and documentation.