Together we create the paper of tomorrow

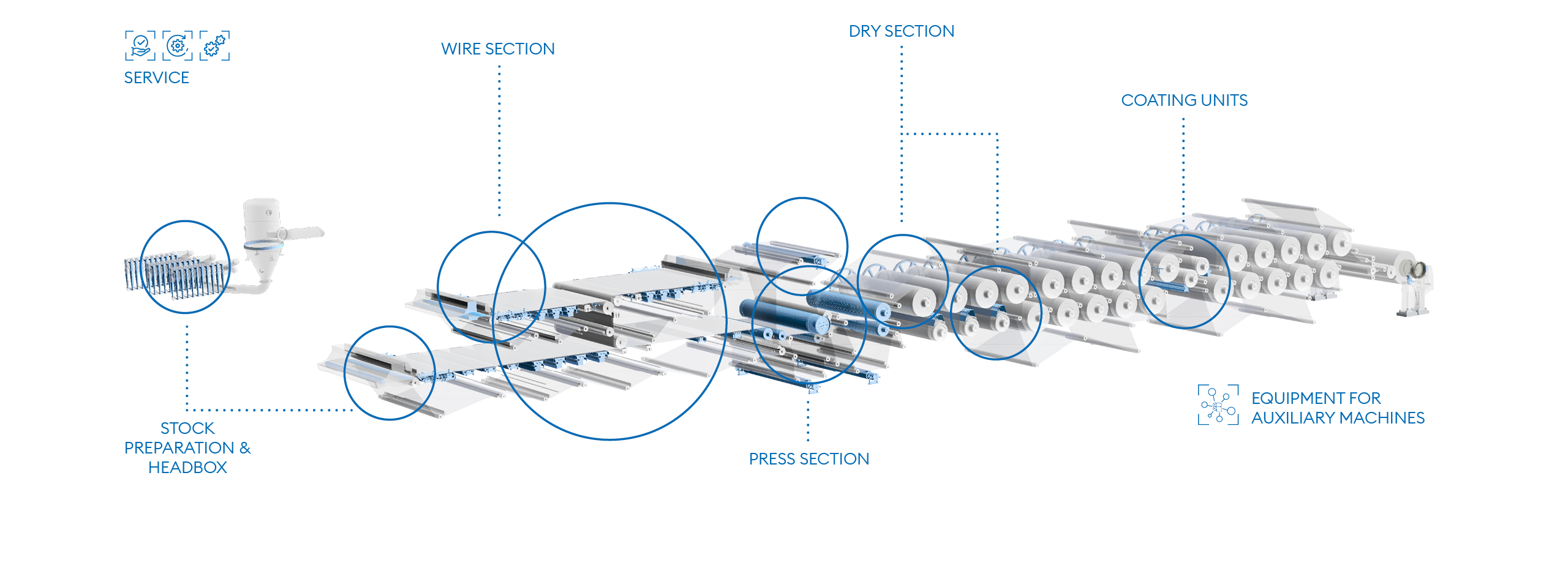

We move the future. As the market leader for premium functional parts in the international Paper Industry, we are driven to increase the performance of our customer's paper and pulp machines. Together with our industry partners, we develop solutions for increased efficiency and quality, cost savings and operational reliability.

Get inspired

Immerse yourself in the world of product applications from Röchling Industrial Oepping. In this reference catalog we present a selection of best practice examples of our products in the paper industry. This catalog shows you how diverse and innovative our solutions are used in various applications. Be inspired and discover the possibilities that our products offer to optimize your processes and increase your efficiency.

"Anyone can produce components. We offer you a complete service package."

Roland Eckerstorfer

Head of Sales Paper Mills

Oepping site

ROI-DRIVEN SOLUTIONS: Performance that pays off.

Röchling Industrial Oepping supplies the right solutions for maximum machine performance and sustainable savings - without compromise. With the right products, optimization can be achieved at the crucial points - whether in terms of energy consumption, drive performance or quality.

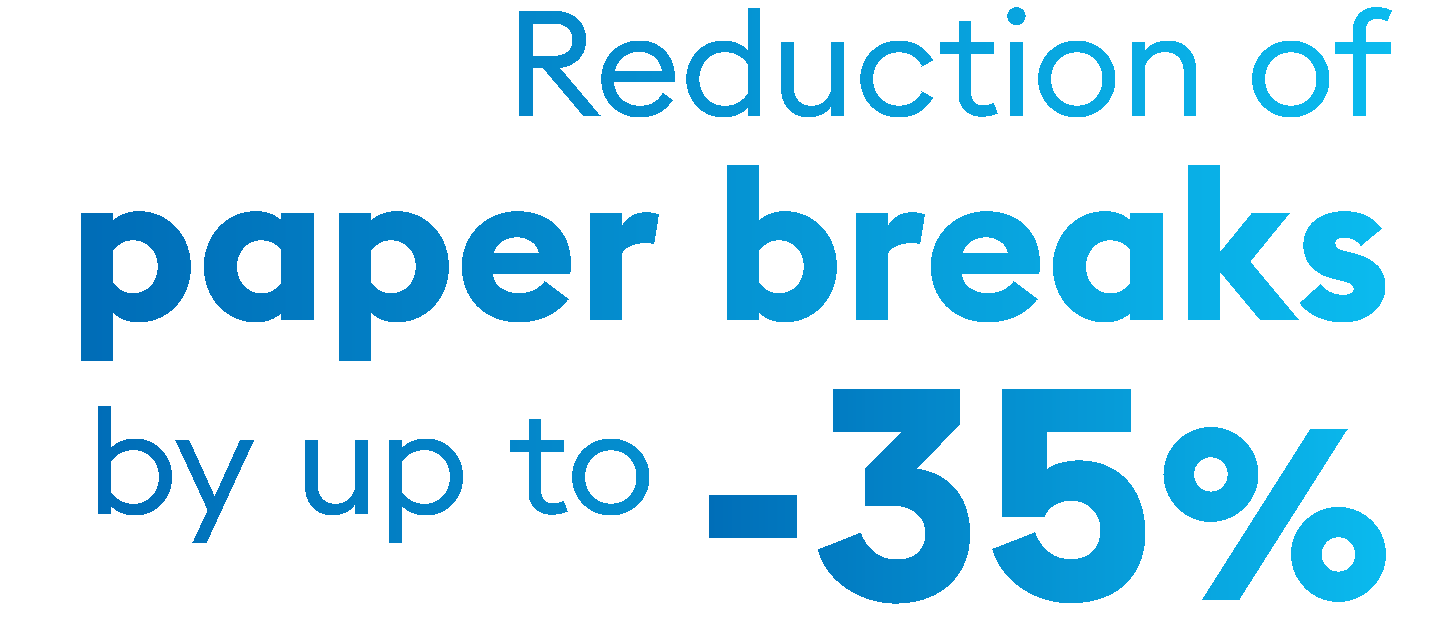

CUSTOMER REFERENCE COMMENTS

With the WireEdgeControl system, paper breaks due to lumps could be completely eliminated. With a downtime of 30 minutes per paper break and €6,000 per hour, the daily savings amounted to an average of €9,000. The ROI was therefore less than one week.

CUSTOMER REFERENCE COMMENTS

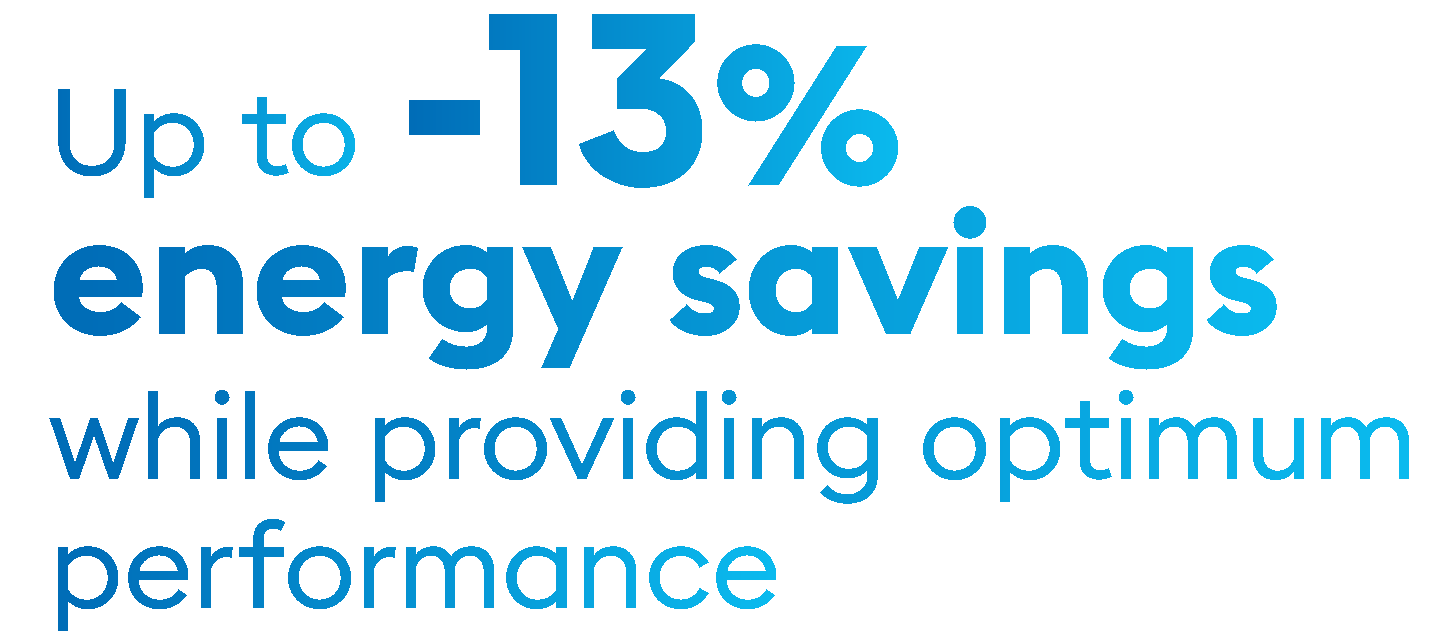

The installation of the premium ceramic RobaCeram PX at a producer of cellulose and paper, corrugated board and packaging materials resulted in a reduction of the drive load from 3664 kW to 3201 kW, leading to energy savings of €367,000 per year at €0.10 per kWh.

The ROI was therefore 5 to 6 months.

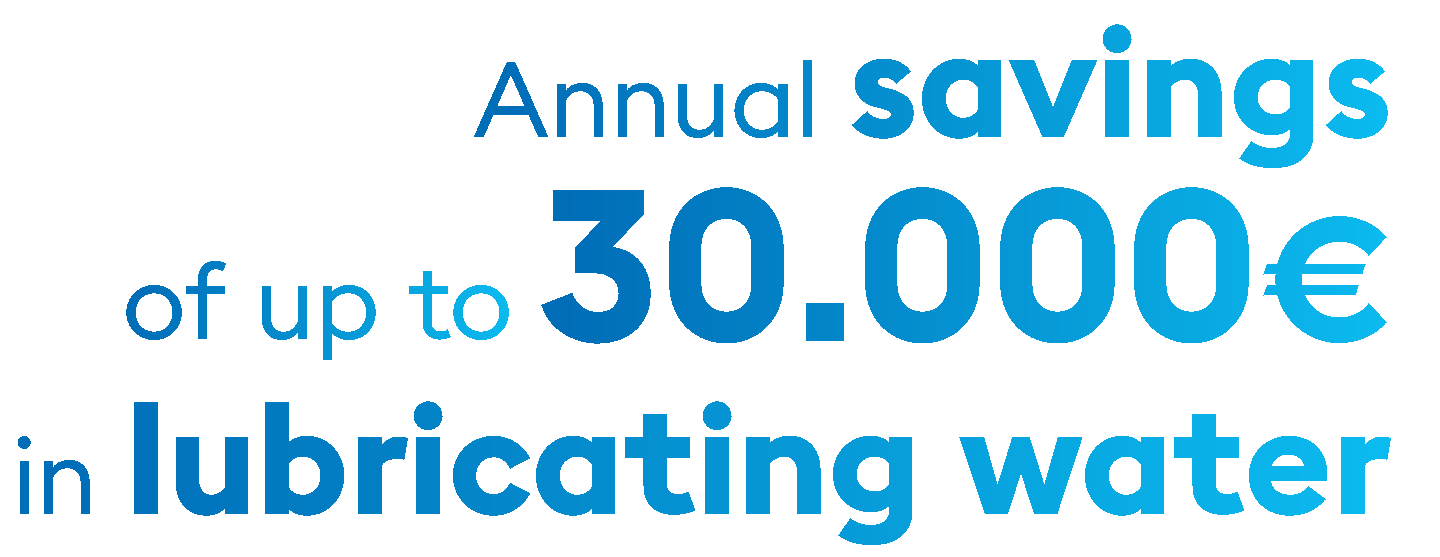

CUSTOMER REFERENCE COMMENTS

Together with the direct lubrication of the sealing strips, the regulated and controlled supply of lubricating water in the SmartRoll leads to a reduction in lubricating water consumption of at least 30%. This adds up to an annual saving of €30,000. With the additional optimization of the contact pressure of the sealing strip, the SmartRoll reduces the drive power of the roll by up to - 30 %. This results in energy savings of up to €50,000.

CUSTOMER REFERENCE COMMENTS

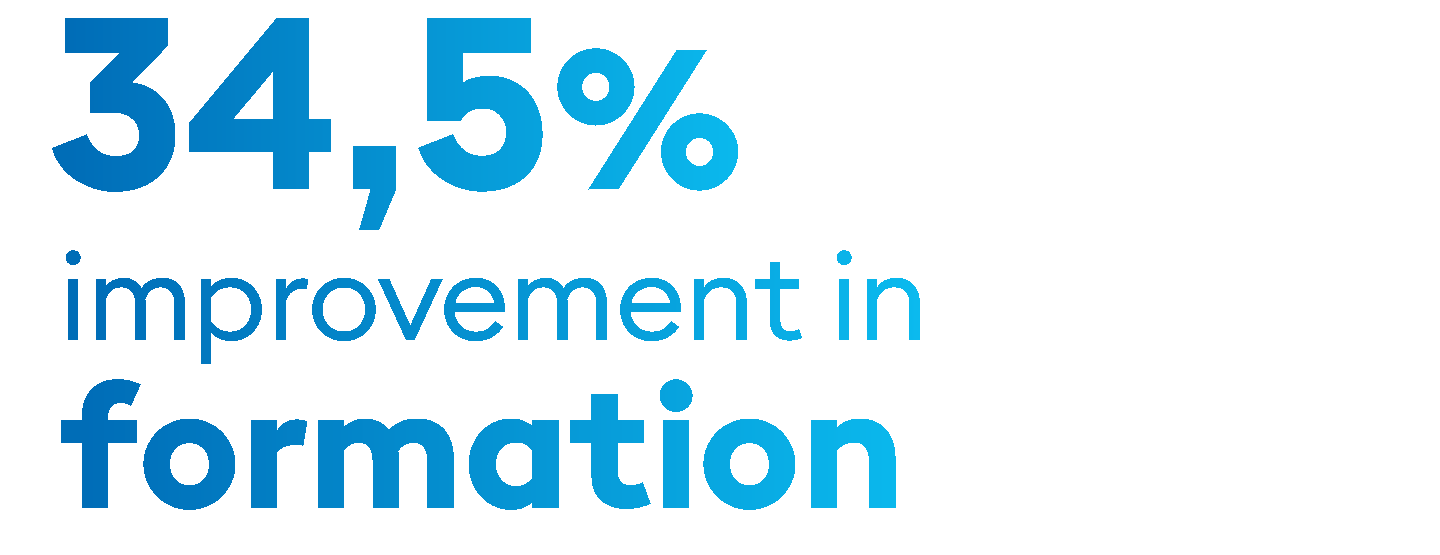

The strategic plan for the SmartTable installation at a customer was to improve the formation and SCT in the cross direction of the machine. The installation included new steel structures with SmartFoils, the WireEdgeControl system and the conversion of the entire vacuum system including 3D scan and vacuum valves. Overall, the formation was improved by 34.4 % and the SCT

in CD was increased by 22.2 %.

CUSTOMER REFERENCE COMMENTS

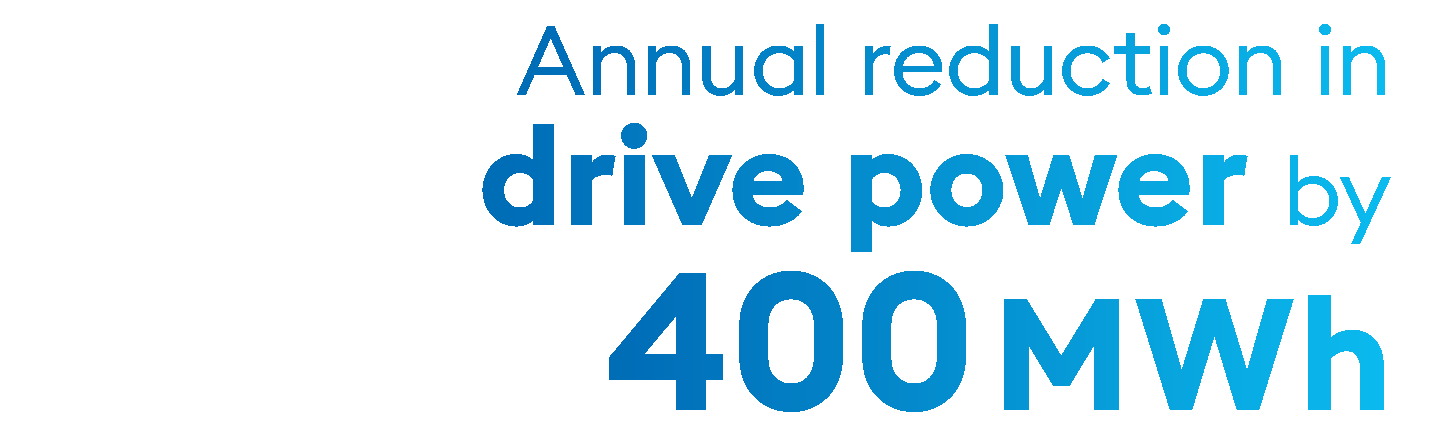

Due to the reduced friction surface, the lower vacuum and therefore also the lower air flow, the drive power was reduced by 400 MWh per year by using the PressSaver. This leads to a cost saving of around €42,000 per year (based on €0.10 per kWh) and achieved an ROI of 6 months.

CUSTOMER REFERENCE COMMENTS

After a detailed analysis of the film press, starch kitchen, and relevant production parameters, our process technologist proposed reducing the dry content before the film press and the solid content of the starch. The improved absorbency of the paper allowed the starch solid content to be reduced from 14–15% to 9–12%. This results in savings of 1.59 tons of starch per day, corresponding to an annual cost reduction of approximately €190,000 at a starch price of €340 per ton.

CUSTOMER REFERENCE COMMENTS

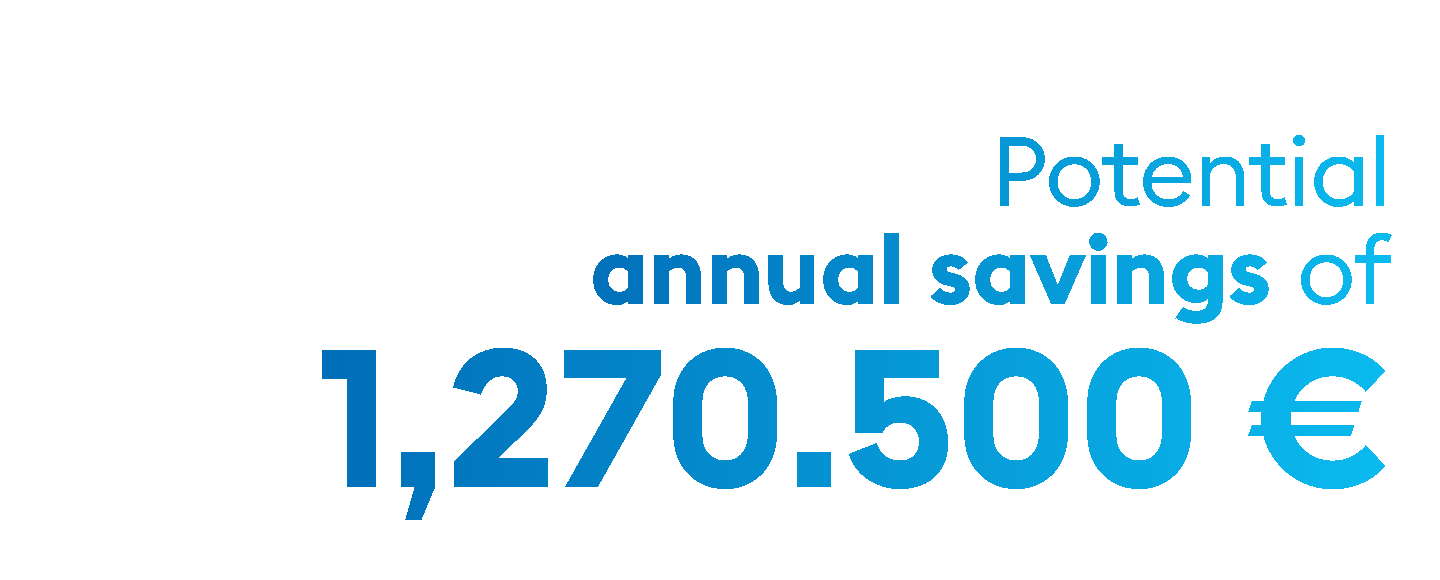

The RobaSmart EZ eco cleaner delivers annual savings of €1,270,586 through reduced water consumption, lower electricity costs by eliminating HP shower pumps and mist separators, and decreased heat energy and chemical usage. Its innovative cleaning technology also provides strong environmental benefits, cutting water consumption by 96–98%, reducing energy demand by up to 70%, and completely eliminating passivation chemicals. These efficiency gains result in an exceptionally short payback period, with a potential ROI of up to four months.

What we stand for.

We strive to be a global pioneer and role model for sustainability and environmental protection. That is driving us to constantly develop our products with intelligent solutions, digitalization and a great deal of common sense.

Because we love solving problems. Providing our customers with the best solutions is our driving force behind new product developments.

Because of our experience we can join our strenghts, come up with new ideas and thus improve the processes of our partners.

The best quality is our standard - no matter if you need high-end plastics, ceramic dewatering elements or sealing strips made of rubber graphite.

Our global network of partners is enabling us to be your local support.

Your contact persons

Stefan Rader

Industry Manager Paper

| Röchling Industrial

T: +43 7289 4611-229

M: SRader@roechling.com

Roland Eckerstorfer

Head of Sales Paper Mills

| Oepping site

T: +43 7289 4611-298

M: REckerstorfer@roechling.com