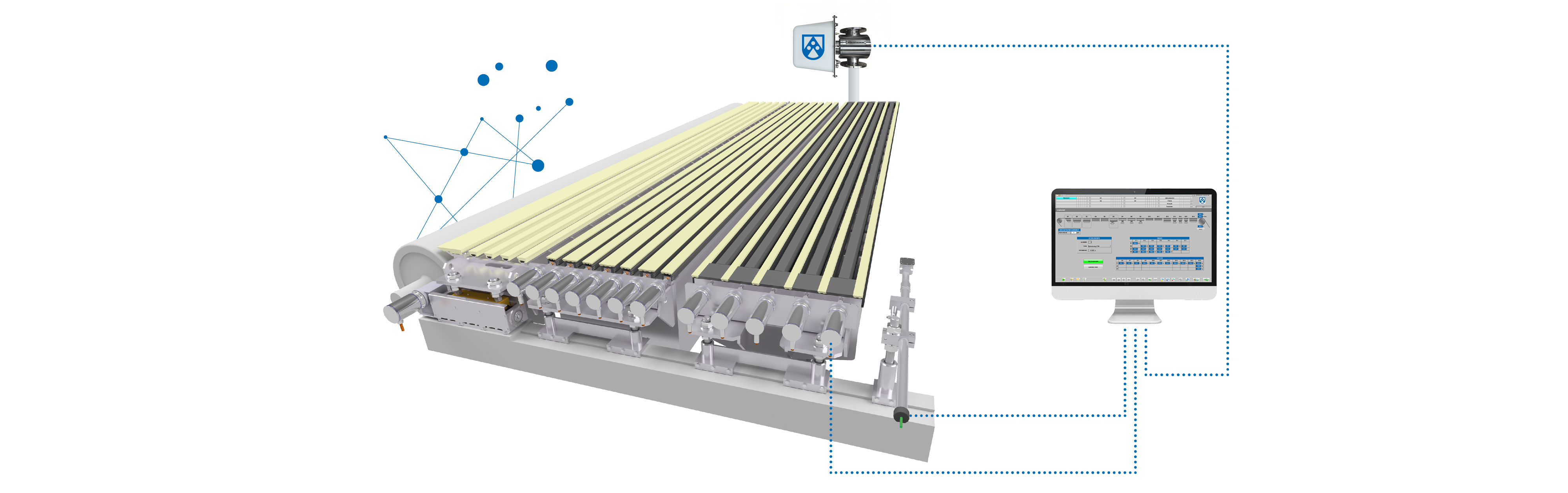

SmartTable

The SmartTable is a completely flexible product family for optimizing the sheet forming zone of Fourdrinier machines. The individual products make it possible to optimally adjust the dewatering performance and activity of each individual grade in a wide product portfolio.

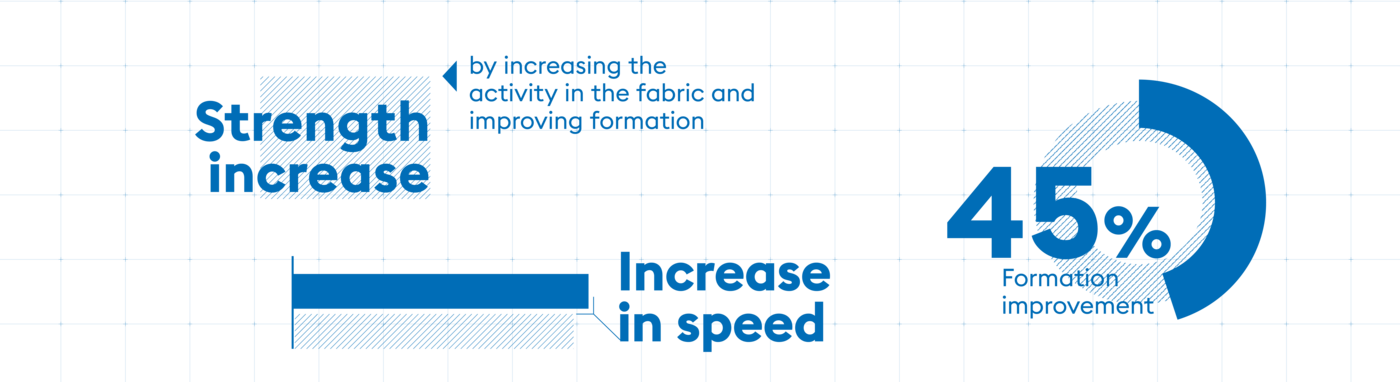

In more than 60 installations, it has already been possible to increase the formation and thus improve the paper quality. Formation improvements of up to 45 % and strength increases of up to 22 % in the standard strength values (RCT CD | SCT CD | CMT |...) can be achieved

Why to choose SmartTable?

What makes the SmartTable so special

Optimized

paper quality

With the SmartTable, every type of paper can be produced optimally in terms of formation, strength and raw material consumption.

Cost

savings

by reducing drive power, lowering steam consumption and fast grade changes with the help of the intelligent SmartTable software.

Short

reaction times

to changing operating conditions using sensors that monitor ongoing operation and enable immediate countermeasures with the smart components.

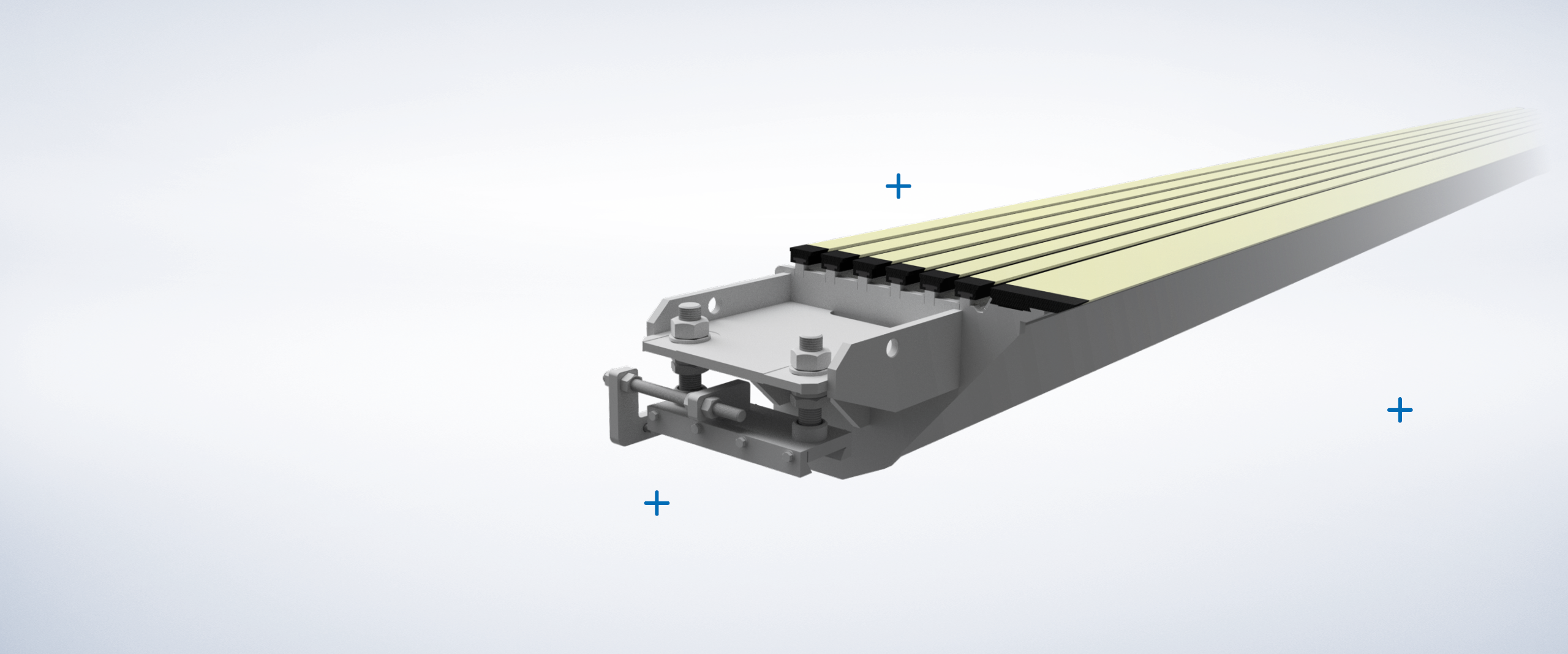

SmartFoils

SmartFoils are adjustable foils that can be individually adjusted in height or angle . By individually optimizing the settings, the dewatering performance can be improved and the activity in the stock significantly increased. This improves the paper quality, individually adjustable for each paper grade. Positioning can be done manually or completely automatically.

Smart HydroFoils

The individual optimization of the foil angle increases the dewatering performance and generates a positive activity impulse.

- Continuously adjustable angle adjustment between 0 and 3 °

- Simple and reliable design for safe operation

- Existing boxes can generally be reused = cost savings

Smart ActivityFoils

Thanks to its individually designed surface, the Activityfoil generates an impulse in the stock. By adjusting the foil height, the influence can be adjusted, increased for more activity or even deactivated for light grades.

- Continuously adjustable in height between 0 and 4 mm

- Simple and reliable design for safe operation

- Existing boxes can generally be reused = cost savings

Smart StepFoils

The height of the stepfoils installed on a StepDrain box can be adjusted.

Height difference and vacuum on the box define the influence on activity and dewatering performance.

- Infinitely adjustable in height between 0 and 4 mm

- Simple and reliable design for safe operation

- Existing boxes can generally be reused = cost savings

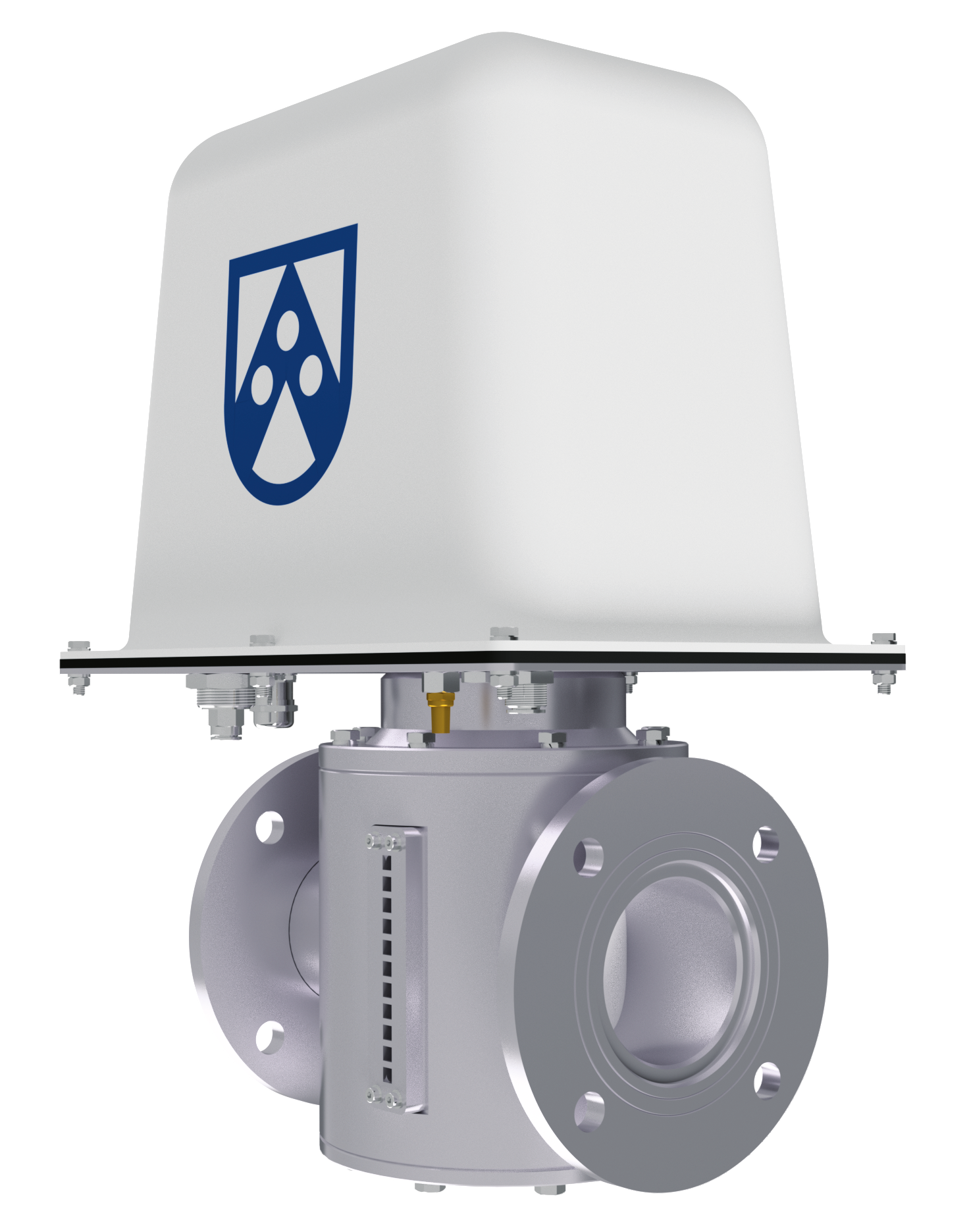

SmartValves

An important part of dewatering efficiency is to optimally control the vacuums individually and thereby increasing the paper quality/dewatering performance. SmartValves from Röchling Industrial Oepping have been specially developed for the requirements in paper machines. Particular attention was paid to durability.

SmartValve-L

Low vacuum valve

The SmartValve-L is an innovative control valve, specially developed for precise control of low vacuums. This is especially important in the low-vacuum range of Vacudrain and Stepdrain boxes.

- Application range <10kPa (=100mBar or 3“ HG)

- Reliable vacuum control thanks to integrated vacuum sensor

- Maintenance-free design

- High reliability thanks to integrated cleaning mechanisms

- Available in dimensions from DN50 (2 inch) to DN150 (6 inch)

SmartValve-H

Medium- and high vacuum valve

The SmartValve-H was specially developed for use in the medium and

high vacuum sector. The valve is suitable for all wet suction and flat suction box positions in the wire section, but also for uhle boxes and even suction rolls in the press section.

- Application range > 10 kPa (=100 mbar or 3“ HG)

- Reliable vacuum control thanks to integrated vacuum sensor

- Maintenance-free design

- High reliability thanks to integrated cleaning mechanisms

- Available in all common sizes: DN80 (3 inch) to DN500 (20 inch)

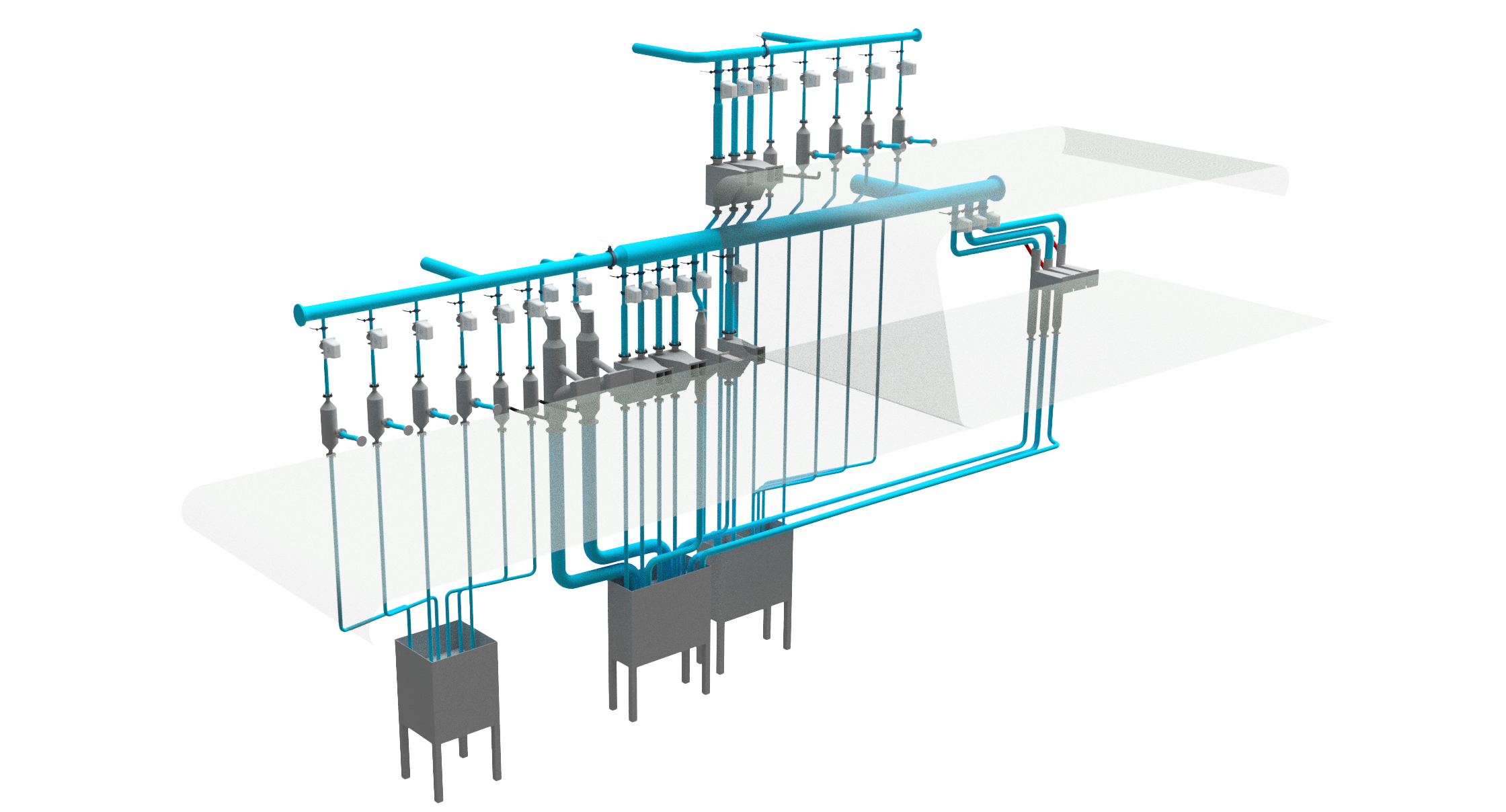

Vacuum Engineering

Vacuum generation accounts for a large proportion of the energy consumption of a paper machine. An optimally designed vacuum configuration is crucial for maximum production speeds and excellent paper quality. To ensure the long-term operational and functional reliability of the vacuum system and the SmartValve control valves installed in it, detailed engineering of the vacuum configuration is always part of a SmartTable project.

The range of services covers the entire piping planning process - starting with a precise 3D scan of the existing system. With the help of high-resolution point clouds, the complex environment is recorded in detail. This forms the basis for designing the pipe dimensions, taking into account the operationally relevant parameters. Finally, the new piping is designed to fit precisely into the existing infrastructure.

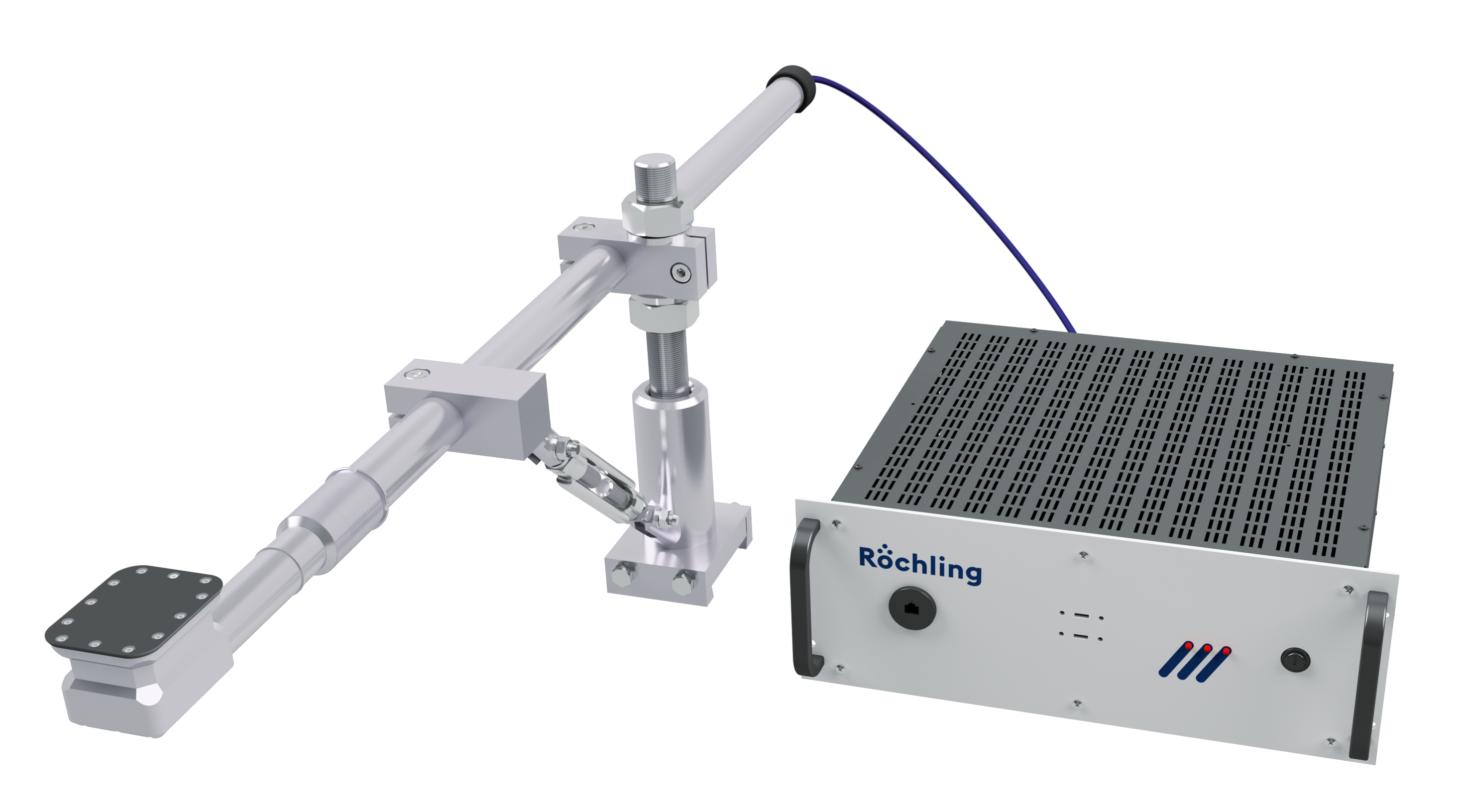

SmartSensor

SmartSENSOR-WS

Specially developed for use in the wire section, this sensor measures the water content in the fabric. This means that the dry content can be displayed before the former at the ply bonding or before the couch roll. Different fiber types, fabric colors, paper types or vibrations have no influence on the measurement.

- Increased efficiency through energy savings

- Increased runability through reduced friction and wear

- Increased quality through production at optimum dry content

Product features

The measuring system is based on a precise microwave measuring principle and covers a wide measuring range from 0 to 48,000 g H₂O/m². With up to 1,024 measurements per second (FFT analysis), it enables fast and reliable detection with high repeatability. The robust stainless steel housing in combination with a low-wear silicon nitride ceramic plate ensures a long service life even under demanding operating conditions.

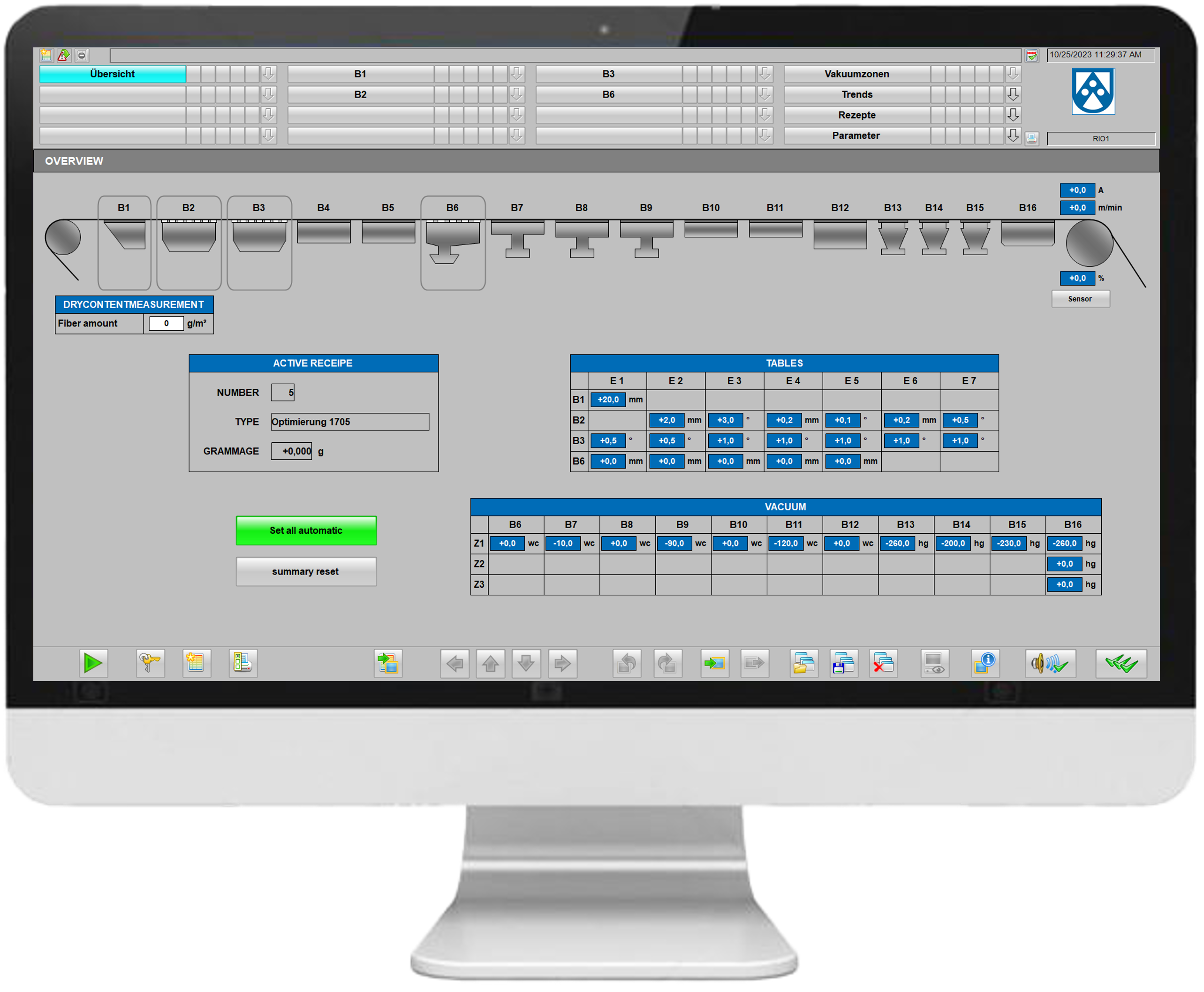

Automation

Automation of the smart components is particularly advantageous when paper grades are changed frequently. Special, maintenance-free stainless steel servo drives and the customized SmartTable software enable grade changes in real time. The system can be installed as a stand-alone system, equipped with a data interface to the process control system or fully integrated into the control system. Röchling Industrial Oepping supplies the complete system, including a stainless steel control cabinet.

ADVANTAGE OF THE SMARTTABLE SOFTWARE

- Minimal cabling and programming work on site

- Shorter commissioning time, as already installed and tested in advance

- Data interface enables detailed data exchange with the process control system

SmartTable AI

The SmartTable made it possible for the first time to control the activity and thus the paper quality. The optimization of paper quality with the SmartTable was carried out using a strobe light and visual evaluation by experienced papermakers. The quality parameters could only be determined in the laboratory in a time-consuming and delayed manner. A direct reaction to changing production parameters was not possible.

SMARTTABLE + SMARTSTRENGTH = SMARTTABLE AI

With SmartTable AI, that‘s history. The adjustment options of the SmartTable, combined with the globally unique SmartStrength online strength sensor, enable a completely new type of quality improvement. According to the motto “Measure what really counts in the end”, the quality parameters are measured online and automatically optimized and maximized by the SmartTable software. This guarantees maximum improvements without the need for optical image recognition of the activity or formation.