Select a different country or region to see specific content for your location.

Industries

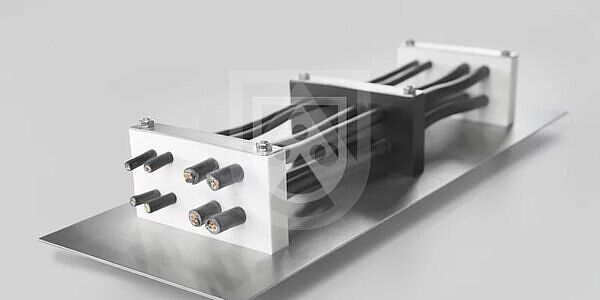

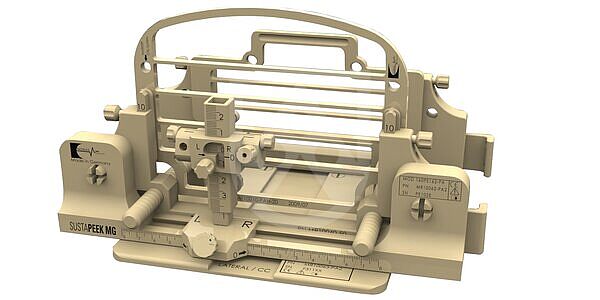

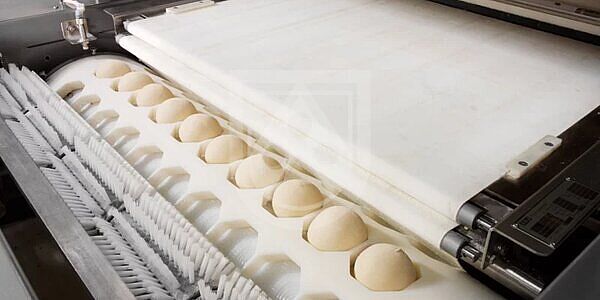

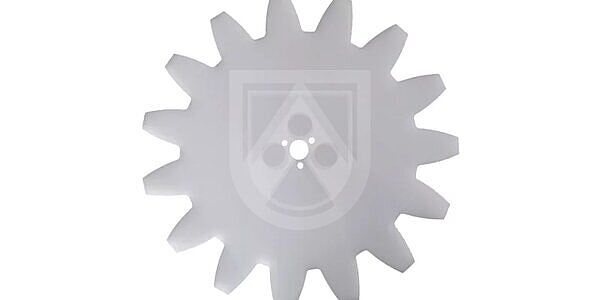

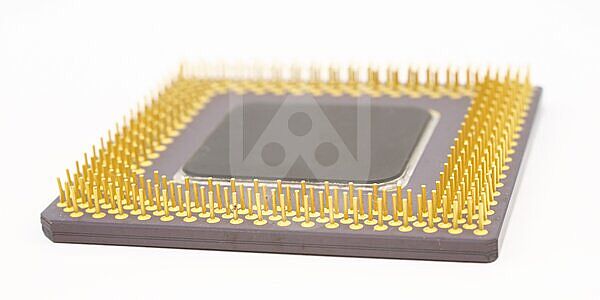

Our high-performance plastics are used in demanding applications such as vehicle construction, food industry, oil & gas, healthcare, and electronics. If you don’t see your industry mentioned here, share your requirements with us! Based on our years of experience, we’ll collaborate with you to develop the right product for your specific application.

![[''] ['']](/fileadmin/_processed_/e/2/csm_roe_oel_und_gas%401x_90cedef17e.jpg)

![[''] ['']](/fileadmin/_processed_/7/7/csm_roe_medizintechnik_und_orthopaedie%401x_66bf8199b3.jpg)

![[''] ['']](/fileadmin/_processed_/d/f/csm_roe_anlagenbau%401x_3bc4b8d4a0.jpg)

![[''] ['']](/fileadmin/_processed_/2/9/csm_roe_fahrzeugbau%401x_8140db9317.jpg)

![[Translate to Chinese:] [Translate to Chinese:]](/fileadmin/_processed_/6/c/csm_Teaser_Erneuerbare-Energien_dbad5e6fd4.jpg)

![[''] ['']](/fileadmin/_processed_/f/3/csm_roe_elektronik%401x_399fee123f.jpg)

![[''] ['']](/fileadmin/_processed_/5/a/csm_roe_luft-_und_raumfahrt%401x_3f4baed99d.jpg)